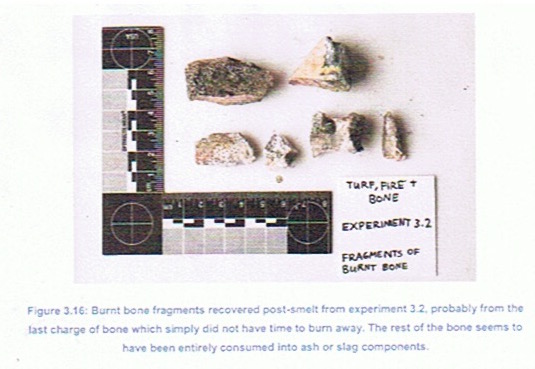

Figure 1B : Smelting area the following morning

'Look at all the BONES...'

Addition of Animal bones into a

Bloomery Iron Smelt

June 20, 2020

Wareham, Ontario

|

|

|

| Figure 2B : Area as examination starts - view to east | Figure 3B : Area as examination starts - view to north | Figure 4B : Laying out the grid rods |

|

|

|

| Figure 5B : Interior of furnace, view from top of shaft | Figure 6B : Detail of furnace interior | Figure 7B : Interior of furnace, view from the extraction arch |

|

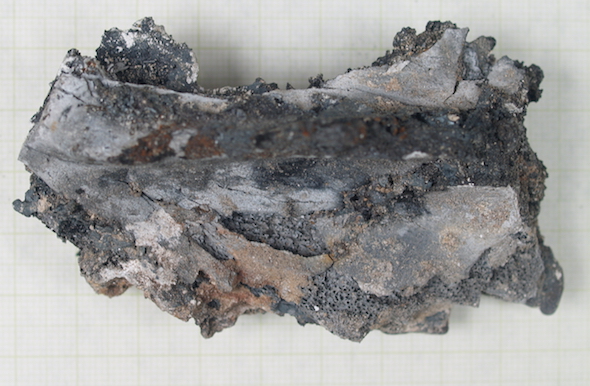

Figure 9B : Largest bone

recovered, section of turkey breast bone from 70 / 100 shown with slag attached side down |

|

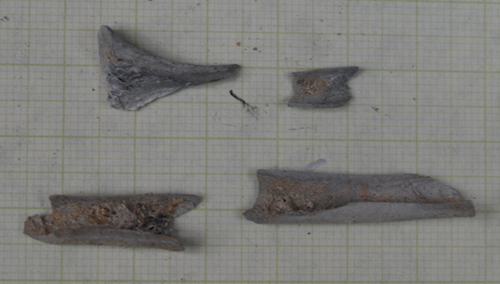

Figure 10B : Fragments of chicken leg bone, primarily recovered from 50 / 60 |

|

Figure 11B : Pieces of solid bone, beef leg bone segments, recovered from 80 / 85 |