Note : This commentary was written in 2016, intended to be my

contribution to the then planned booklet describing the Turf to

Tools project, which would have included a number of other

authors. Readers will find much of this material incorporated into

the finished paper from 2023.

Turf to Tools

A View from an Artisan Maker

Darrell Markewitz

Turf to Tools was initially conceived as "... an ongoing

investigation in to landscape, material and craft, inspired by local

archeological investigations in Rhynie, Aberdeenshire."

I come from a camp that lays between the pure conceptual Artist and

the Technician. As I understand these terms at SSW, the Artist being

defined as one most concerned with developing ideas. The Technician

being more concentrated on physical methods. As an Artisan Maker, my

own work is often bounded by functional considerations, but I strive

to design an object still pleasing to look at. There may be an

element of the thought provoking as well, but most commonly this

remains secondary to the demands of function and the desires of

form.

As an individual, I find myself a bridge between a number of quite

different fields. I have a long working experience in the very

technical realm of the blacksmith / metalworker. Along with having

come from an formal education in art school. Being known as

knowledgeable in early North European, especially Viking Age,

material culture - and the public presentation of the same. In

recent years becoming more and more involved in experimental

archaeology (itself a span between the academic researcher and the

practical field worker).

Each 'camp' has its own method of both approaching subjects, and

often distinctive (even conflicting!) descriptive language. Added to

this ball of string is the fact that there are international

differences, including (certainly at the Scottish Sculpture

Workshop) multiple language users.

Given I'm from Canada, with a large body of work ranging over many

types, and with 'many irons in the fire', what can I say about the

Turf to Tools project?

My involvement with Turf to Tools came in through the side door.

Eden Jolly had initiated what I would call a 'proof of concept' for

the over reaching frame of the project : utilizing local raw

materials, through regional historic based methods, to create

functional objects. His background research into this all lead him

to my own internet available documentation. A personal conversation

started via e-mail, helping him with his first attempt at a bloomery

iron smelt. Someplace along this line, Nuno Sacramento had contacted

me to see if I would be interested in coming to SSW and directly

participating in the project. In this case, those 'many irons'

appeared to provide an ideal mix of historical knowledge, technical

skill, practical experience, and (perhaps) artistic vision needed.

The first phase in 2014 most certainly was shaped by the archaeology

of nearby Rhynie, for which the inclusion of Dr. Gordon Noble on the

project would prove of importance. So to start, T2T was framed to a

'Pictish' cultural set : North Eastern Scotland, post Roman to pre -

Viking (so 400 - 800 AD). It is a period where the minor chiefdoms

are expanding to small kingdoms, and Rhynie appears to be the site

of one of those political centres. Historically this period presents

some major problems, as this is a material culture not well

represented by artifact in archaeology. Importantly at that point

Christianity is becoming the major religion. (This significant

because one change with Christian conversion is the end of a more

ancient practice of burial with a person's life goods, thus now

limiting objects into the artifact record, especially those of daily

life.)

Evidence of ancient iron smelting technology is almost always

fractured, and honestly not well understood. Looking for

specifically first Scottish, then narrowed to Pictish period samples

at first seemed unlikely. Fortunately, it proved possible to find

some descriptions of an excavation of a small scale historic iron

production site at Culduthel, just outside Inverness. Both the close

location, and the rough dating from 200 to 400 AD, is almost good as

it could be within the random nature of archaeological discoveries.

Past work in the realm of experimental archaeology would prove

critical here, allowing for a fuller understanding of exactly how

available iron ore was transformed into workable iron bars.

The enigmatic figure found in 1978 carved in a large stone slab, the

Rhynie Man, would channel the 'object' part of the undertaking. The

cartoon like figure, likely created some time about 400 - 600 AD,

holds over his shoulder an axe. Who is depicted? What is and Why is

that axe shown? What is the original reason for the exaggerated

details : pointed teeth, big hooked nose, hair or head-dress? To

make this all more difficult, no artifact axes have been found in

Scotland for the period of reference. Within all of Great Britain,

only a mere handful have been found. Searching for a possible

artifact prototype would prove not only difficult, but

interpretations of that sample became a point of discussion within

the project.

Checking the air system, T2T smelt 1.2, 2014

(image by Kelly Probyn-Smith)

The basic equipment design employed is what I call a 'short shaft'

type of direct reduction iron smelting furnace. This consists of a

cylindrical or slightly tapered clay cobb body, about 60 to 70 cm

tall and roughly 25 cm interior diameter. The walls are hand built

up from a mix of 1/3 course sand, 1/3 clay and 1/3 shredded dry

horse manure. The manure addition reinforces, gives steam on drying

some place to expand and burns away on the interior to create a

primitive refractory material. A tuyere pipe is inserted about 15 -

20 cm above the base level, standing 5 cm or so proud of the

interior wall. The ideal angle for this is about 20 degrees

downwards, and this serves to deliver the air blast into the

interior.

Hardwood charcoal is the normal fuel (almost universally), and needs

to be of a certain size. Ore as well needs to crushed to an ideal

size, which varies depending on type of ore. There is a dance

between ore type, charcoal, clay used and the final ideal size and

layout of the furnace, and the amount of air, both volume and

pressure. Change too much of one, and all the other elements need to

be modified. (This is primarily why historic furnaces vary so much

for different physical locations.) Past experience has shown for

this type of furnace, the ideal rate of burning is 2 kg of charcoal

(about 8 litres) every 8 - 10 minutes, a process that continues for

many hours.

Ore is mixed evenly through the charcoal as it is added to the top

of the furnace. Iron oxide ore meets hot carbon monoxide gas

from the burning charcoal. This wants to be carbon dioxide,

so the oxygen is reduced from the ore, leaving fine metallic iron

particles behind. With an interior at about their welding

temperature, the particles stick together (sinter) like dark brown

sugar does. This material falls to the bottom of the furnace. Also

falling to the bottom is a rough glass formed from sand (silica) in

the ore, melted clay walls and ash from the charcoal. This also

falls, hits the cold bottom of the furnace and freezes, but remains

liquid on the top, nearest the air blast of the tuyere. Iron falls

into this slag bowl, sinking through the hot liquid glass and

stopping on the more solid bottom. (Think of a chocolate covered

cherry, the chocolate the slag bowl, the cherry the iron bloom, the

liquid slag the sugar syrup.) At the end of the smelt, the base of

the furnace is opened to expose and crack apart the slag bowl, then

grab the metallic bloom that (hopefully) has been produced.

And yes - an amazing number of things can go wrong in all this!

As with any complex project, mere mechanical problems often

interrupted the chain of exploration.

Building the initial iron smelting furnace was fairly straight

forward, overall based on Culduthel, but including those elements

found through experience most likely to ensure effective results.

What I call a 'short shaft', in this case mounted on a plinth made

of stones and This base design was pre-tested at my home workshop in

Canada months in advance. Application of a construction suggestion

by George Beasley, based on his (extensive) experience with cast

iron furnace operations was quite helpful.

The first test included use of a unique local iron ore called

Macaulayite, which proved not to be an effective raw resource. (Note

that the better part of two days effort and the expenditure of some

60 plus kg of prepared charcoal were expended!) The end result here

was a small iron bloom at 2.3 kg, an ore to metal yield of only 7.5

%.

This second firing using primarily industrial taconite ore should

have produced significantly better results, but in the end the bloom

was only 2.9 kg, a 11.5 % yield. Although jokes were made about

Scottish weather, the more likely reason was the air supply system,

via a small electric leaf blower.

The third test required the building of a second furnace. This

because the first furnace had been constructed on a wooden pallet

(topped with concrete paving slabs) to allow it to be shifted around

the work area. As it happened, moving a clay smelting furnace proved

not such a great idea, and resulted in extensively damaging the

structure. Input from artist Deirdre O'Mahony lead to a question

about utilizing peat as a fuel source. As the new furnace needed to

be baked dry, a test using suitably broken up modern commercial peat

pellets as fuel was undertaken. Although only a short burn,

thermocouple readings made suggested temperatures into the correct

operating range might prove possible (1140 - 1250 C recorded).

The third test would utilize a proven ore type, an analog developed

specifically to mimic naturally found primary bog iron ore. The

furnace design was essentially the same as before. The most major

change was the use of a stronger blower, ensuring better delivered

pressure to better force air into the furnace. In addition to the

primary iron making activity, Emma Harrison would contribute both

her effort but an additional experimental process at the close of

the smelt. For her own research project, a total of 4 kg of raw bone

was added in an attempt to create a high calcium layer to the top of

the bloom mass. Taken together, the skill of the team and the use of

proven elements showed in the excellent results. This time an

extremely dense 11.6 kg bloom was produced, a yield of 29%. This

bloom later proved so massive that staff at the University of

Aberdeen were unable (with modern tools!) to effectively section it.

Along side all this effort was the 'bloom to object' part of the

project. This was directly related to Rhynie Man, specifically that

axe. I had made a prototype back in my Ontario workshop, conforming

to earlier research I had undertaken to Viking Age tool axes. To my

eye, the Rhynie Man's axe was a well known early 800's fine tool axe

type, quite common in Norway. These slender blades, mounted to a 60

cm or so handle (as seen with Rhynie Man's) are designed to take a

fine sliced shaving off a wooden beam, for either house or ship

construction. Of course, any tool balanced for fine cuts to wood

will also make a deadly weapon. In my opinion, the Rhynie Man Axe

was an accurate depiction of a somewhat expensive, but purely

functional, tool / weapon.

Axe Prototypes made in T2T, Rhynie on left,

Sutton Hoo on right

As mentioned, there are no artifact axes that have been found in

Scotland from the Pictish period, and very few found in England

either. One of the few well known is the 'axe hammer' from the

Sutton Hoo ship burial in East Anglia. This is clearly a Saxon

culture, has many pagan elements, but is roughly contemporary at 624

AD.

As part of T2T, I hand forged a rough replica of that object for

direct comparison with the Rhynie axe. With the Sutton Hoo axe in

hand, again a likely use suggests itself. Even with the lighter axe

head and the heavier shaped iron handle, Sutton Hoo certainly feels

like a weapon intended for use on horse back. All though it is most

likely we can never know for sure, but the creation of accurate

replicas brings ancient objects to life.

As a further extension into exploring the world of Rhynie Man, Kelly

Probyn-Smith undertook working towards making a replica of the axe

headed pin that had just been uncovered at the excavations. This

small straight pin was a type most commonly used to secure a cloak

at neck or shoulder (depending on the sex of the user). The upper

terminal flared to an axe shape on one side, the other side being

drawn out then formed to a spiral coil. This appeared on the

radiograph reference images to end in serpent's head. Forging such a

small object presents its own set of difficulties. Curiously the

small set of 'jeweller's' sized tongs also recovered in the 2014

excavations at Rhynie would be the perfect tool for such delicate

work.

After all this historic and technically focused exploration, I was

certainly very keen to also create a physical object with a more

modern context. I selected half of the first bloom created, and

forged out a small bowl. Bloom iron is different than modern metals,

in terms of alloy content, physical structure and importantly,

working character under the blacksmith's hammer. As an artist, I

continue to be very interested in working with these differences,

and how in these in combination mark a finished object.

The second phase in September of 2016, would continue exploring both

the initial concepts, and new aspects based on the discoveries from

phase one. Three more iron smelts would be undertaken again using

the same basic furnace design.

A field trip in 2014 was to the nearby Lecht Mine, part of

investigating the land and local resources. This open cutting along

the edge of a small rift in the hills was operated in two phases

historically. In the early 1800's, manganese ore was extracted

there, causing the building of a stone structure with a small water

powered crushing mill (the shell of which still remains). Earlier in

the mid 1700's, iron ore was extracted. I had stumbled over

(literally!) a thin vertical vein of what looked like it might be

usable geothite ore. At the start of the 2016 phase, we returned and

gathered four pails of this ore, quality varying by the individuals

gathering. The ore gathered at Lecht was roasted, sorted and

crushed.

A new furnace was constructed, very similar in size and layout to

the ones used in Phase 1. One difference for the first smelt was the

use of a copper tube as the tuyere. This was forged into a thick

walled taper, about 1.5 cm interior diameter on the insert end, and

40 cm long.The operation of the smelter was fairly standard, save

that considerably more iron rich slag was created than normally

seen. This required four major slag taping interventions to drain

the excess lest it 'drown' the air flow at the tuyere. In the end a

large block of yellow hot slag bowl was extracted, but with

hammering only a small amount of iron was found. Total production

3.5 kg, yield at 8%. This indicates the ore gathered (remaining?) at

Lecht, although able to create iron, is too low in usable iron

content to balance the considerable effort and expenditure of other

resources to effectively extract it.

Smelt two was a full scale test of peat as a potential fuel.

Commercially harvested and compressed pellet peat, sold as home heat

fuel, was purchased. Without specific experience, the peat was

broken to pieces similar to those proven effective with hardwood

charcoal. Again the addition and measured consumption was against

pails of 2 kg. The ore used was a red iron oxide analog mix. One

other modification was the addition of 3 kg of crushed high iron

content slag for the initial charges. Although the peat fuel

certainly appeared to be consumed faster than with charcoal,

temperatures measured by thermocouple indicated lower than normal

internal temperatures. At the end of the smelt, this was born out by

the results, with only 1.5 kg of fragmented iron being recovered,

yield at just over 4 %. A large quantity of foil like metallic

gromps were also collected. Both suggest iron was being reduced, but

temperatures were not quite hot enough to effectively sinter this

together into a solid bloom mass.

Although this was intended to be the end of the smelting events at

T2T2, Eden and Uist Corrigan decided to undertake an additional test

(while they had me around to observe and assist as needed). Enough

charcoal and taconite, both proven components, remained on hand. The

furnace that was initially constructed proved extremely durable,

needing only minor repairs around the extraction arch each time. For

this last smelt, a short piece of high temperature ceramic kiln

support tube replaced the copper for tuyere, into the same position.

Once again 3 kg of iron slag was added as the first charges. (The

logic here is to more quickly form the required bottom slag bowl.)

After all the available taconite ore was added, a further amount of

mixed Lecht ore and metallic gromps from smelt 2B were also

included. Another change was the addition of a small slag port to

the bottom of the furnace, making possible a continuous tapping

process. The end result was excellent, with an extremely large and

compact bloom at 9 kg, yield at 26 %. This certainly proved the

effectiveness of the furnace operation - and the skill of the

working team.

Although the intent of phase two was to devote several working days

to the second stage process, bloom to bar, followed by the third

stage, bar to object, this in the end did not prove possible.

Although work had begun earlier on a new 'professional' level

blacksmith forge for SSW, this equipment suffered some teething

problems in getting it working correctly. Work was also massively

impacted by what proved a serious problem in securing effective coal

fuel. After several quite unsatisfactory tests, and considerable

outside consultation, it was found that the 'best' (if not only)

available coal was in fact imported from Poland. This itself was a

major surprise, and certainly reflects directly back the the framing

concept of human impact on natural resources.

One conceptual project that arose during the 2016 session was one

suggested by an even older cultural practice relating to iron

objects and landscape. In the more distant Celtic Iron Age, ornate

and expensive objects (particularly jewellery and weapons), where

often returned to the bog as sacrifices. Weapons used were often

bent beyond use - symbolically 'killed' - before being deposited.

Everyone on the Turf to Tools team thought the ideal of making a

finished object from our precious bloom iron, then returning it to

the bog from which the starting ore sprang, would make a powerful

last stage to the overall project.

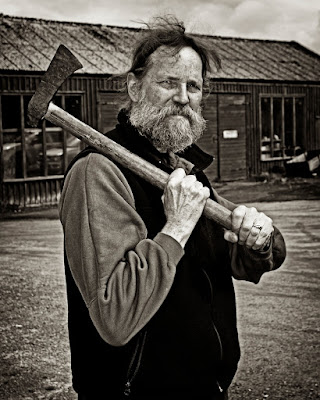

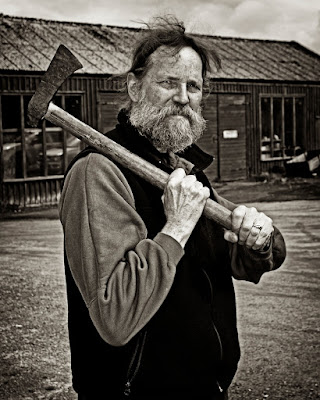

Posing as Rhynie Man at SSW, 2014 (image by David Porter)

Posing as Rhynie Man at SSW, 2014 (image by David Porter)