Stacking Up

- on constructing clay furnace walls

Introduction:

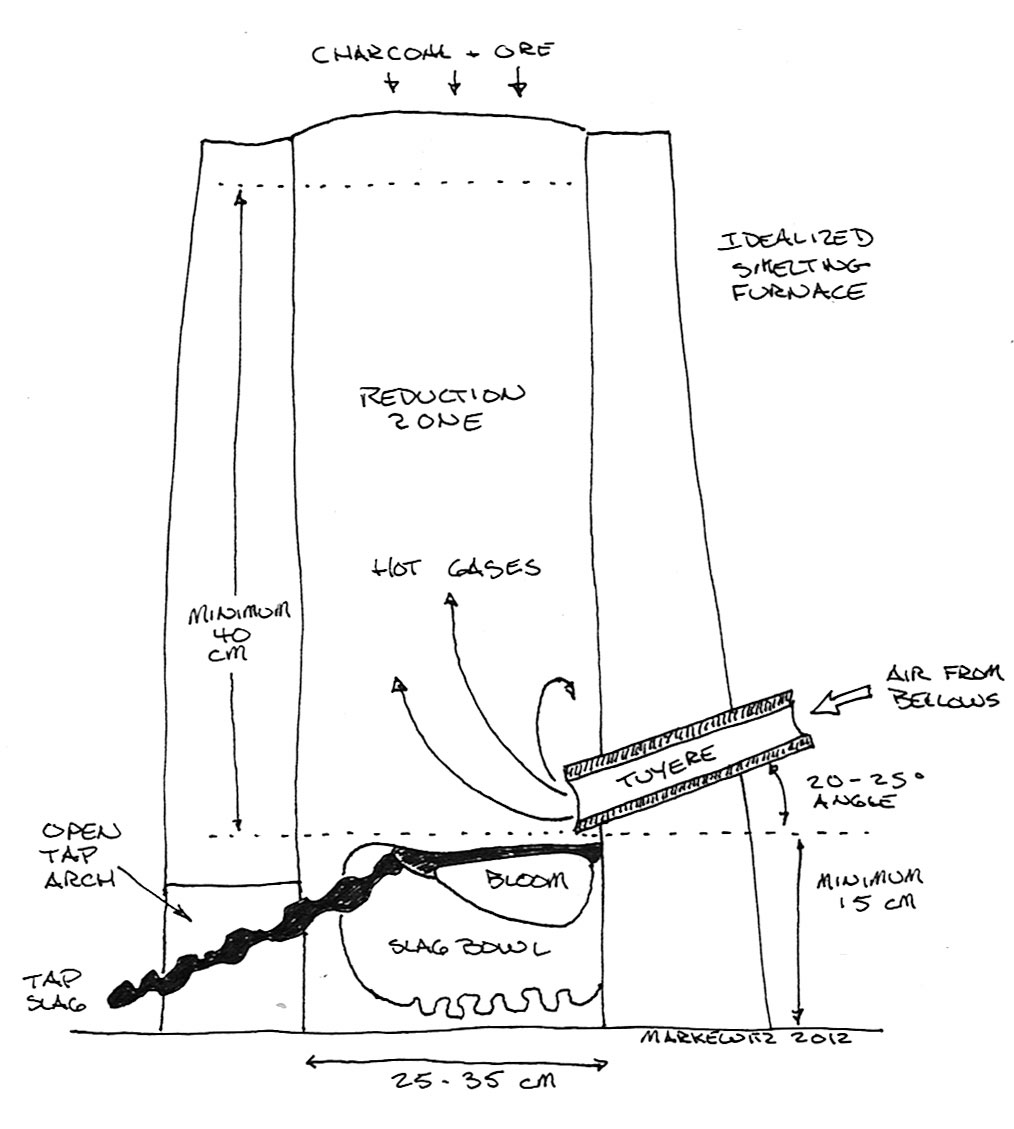

There are a number of considerations that go into

the construction of the total shaft (a) height for a direct

process bloomery furnace. This discussion is going to be focused on

small scale builds, with internal diameters in the range of 25 to 30

cm, particularly with prototypes found in Northern Europe, post

Roman to Medieval (so 400 - 1100 AD). These furnaces all had

some kind of human powered forced air, equipment that sets limits on

just how much total air can be delivered, so also how large an

internal volume can be effectively combusted.

Archaeologically, it is rare to find the upper

portion of any furnace, more common are the remains of only lower

walls framing a slag bowl, usually not extending beyond the mounting

level of the tuyere. There are functional requirements to the

furnace stack (b) height (distance above tuyere) as

demonstrated by extensive experimental smelts, with at least 40 cm

proven a minimum, a measurement of 50 + cm considered ideal.

With the addition of enough space for a functional slag bowl to

allow for the proper collection of the developing iron bloom,

typically 15 - 20 cm, this gives a total furnace shaft height of

such furnaces into the range of 55 - 70 cm. (1)

Diagram of an idealized bloomery furnace

Ideally, a furnace should be constructed to

contain the reactive gasses produced through ignition of charcoal

which are required for the reduction chemistry. (A second

consideration for preventing any side venting is simply making it

possible to work safely around the furnace!) In experimental work,

it has been shown that there are loosely two different ways that a

clay built furnace can survive the kind of operational temperatures

(in the range of 1150 - 1250 + C) necessary. (2)

One format is to use a relatively thin, but

previously fired to ceramic, wall structure. A design developed by Lee

Sauder and Mike McCarthy as the ’Flue Tyle’ teaching

furnace, in this case using a standard chimney flue liner section,

(3) normally a rounded square at about 28 cm ID x 60 cm tall. Here

the wall is composed of a lower fire temperature earthenware at

about 1.5 cm thick, with an additional 1.5 to 2.5 cm clay mixed with

shredded cellulose added to the exterior. With this build, excess

heat radiates off this thin wall structure, keeping the material

from melting during firing. It should be noted that this principle

of construction does not appear in the archaeology however.

Flue Tyle furnace - Early Iron 2, 2005

Skip Williams feeds, behind (L-R) Jake Keen, Mike

McCarthy, Lee Sauder

Historical furnaces are all built on the ‘make it

thick enough to endure’ principle. Furnaces can be either partially

or fully earth banked, or built free standing. Even those furnaces

completely earth bound still will require some kind of semi durable

liner to hold that earth in place. Loosely grouped, furnaces

(or liners) may be constructed of large stone slabs, stacked stone

blocks (with varying amounts of clay fill), or completely composed

of clay (often with additives). (4)

With stone, the pieces need to be of some igneous

type, again to survive exposure to the operating temperatures

produced. Building with stone slabs can prove difficult, as stone

types and forms are determined by local geography, and also in

terms of acquiring pieces of suitable size against thickness.

Corners and seams may still require some fill, again clay being the

ideal caulking material. (Mitigated by the skill at stone building

of the makers!) One additional problem observed with stone slab

construction is that this tends to create a square or rectangular

cross section. The air blast from a single tuyere within a

rectangular furnace tends to produce a D shaped ignition pattern

(flat side centred on tuyere point). This can become a problem with

low air volume / pressure into larger sized furnaces, where the two

back corners may not be fully able to ignite (5)

Stone Slab build – Experiment 2, Wareham,

2002

Poor ignition into the rear corners.

Use of ‘stone block’ construction has the

advantage of making for massively thick walls. Effort during

construction is invested against durability over many firing cycles.

Gaps between individual stones must still be sealed, again with clay

the ideal material. This clay will be exposed to less heat damage,

but given the raw volume that may be required, there may not be any

reduction in the total amount of clay required over a self self

supporting clay build. The stone block method of building best suits

a more ‘industrial’ level of repeated iron production.

Stone blocks in clay fill, lower base only –

Dalarna, Sweden

Image from I. Serning *

Considering Full Clay Builds :

The final construction material, of greatest

interest here, is the use of clay or clay mixes as the wall

material. There obviously will need to be a consideration of

the qualities of available clay plus modifications possible via

various additives, and how this effects both simple handing and

stability during construction, to the final heat resistance dynamic

of the finished build. Generally it has been the experience over a

large number of working smelts by various teams that a clay wall

thickness of 5 cm is a bare minimum, with 7 - 8 + cm thickness in

the lower sections more practical.

Rare remaining full clay build, 80 cm tall

– Lodenice, Bohemia

Note that the tuyere point (most heat erosion) and

extraction arch are made as a separate, replaceable, wall

section.

Image from R. Pleiner *

Individual natural clay bodies vary enormously

between locations, importantly here in terms of their eventual

melting temperatures. Some clays may melt completely at the

operational ranges of the iron smelting furnace. One simple way to

modify this is to add a volume of ‘sand’ into the mixture. (6)

Generally sand types have higher meting points than clays, so

addition will increase endurance to high temperatures. Sand also

does not absorb water, so higher sand mixes tend to be much more

stable during the initial drying phase of construction, where high

clay compositions can shrink considerably (10 - 15% not uncommon).

Balanced against this increase in refractory quality is that adding

sand makes the starting build mix less ‘sticky’, requiring more care

during the construction. (7)

The DARC team started experimenting with

adding various organic materials to a clay and sand mix quite early

our long series of test smelts, borrowing ideas from both other

practical workers and from examples of the use of clay ‘cobb’ in

constructing things like bread baking ovens and pottery kilns. It

was discovered that chopped straw or hay (available from local farms

around Wareham) could provide good re-enforcement against cracking,

but also created problems with both consistent mixing and in

blending together of individual ‘lumps’ when building walls up.

Generally, walls using mixes including roughly 1/3 by volume chopped

straw proved easiest to construct when these were thicker, in the

range of 7 - 8 cm. With our own builds, inclusion of the larger

diameter pieces of straw were clearly visible after firing. Although

the plant materials burned away well before clay had heated to it’s

sintering temperature, the remaining voids are obvious visually.

Clay with field grass, detail. Furnace built

June 2006, fired a total of 5 times, then left to naturally

erode.

This image taken June 2021, void lines from burned away

vegetation clearly visible.

Work by Michael Nissen, demonstrated at

the ‘Iron in Thy’ (Denmark) symposium in 2008, suggested the use of

dry, shredded, horse manure as a good organic binder. (8) The first

full furnace build using what has become our standard mix of 1/3 by

volume dry clay, course sand, and (dry!) manure was undertaken here

in May 2012. Although a more subtle effect after a furnace is fired,

inclusion of this material is also visible to the eye.

Clay mixed with course sand (white) and

shredded horse manure, after firing.

#88 - Icelandic 9 (3A), June 2021

Considering Clay Building Methods :

The first full build with clay a the wall

material was in June of 2004. This was a group effort, with a lot of

individuals involved in preparing the components for the mix,

blending these together, then building up the furnace walls. Two

major problems became quickly apparent, maintaining consistency of

the material, and varying skill in the actual build. In attempting

to add more clay to build upwards, the helpful (but unpractised)

hands ended up pushing as much downwards as they blended new

material. The end result, despite the volume of clay used, was a

very short furnace with very thick walls.

Finding the ideal consistency of mixture, here

meaning level of plasticity created by amount of water added to the

dry ingredients, is a continuing problem, even as individual members

of the team have acquired considerable experience gained from

building scores of furnaces over the last two decades. Generally,

those mixtures with higher water content, being softer, are easier

to both physically shape, and to merge successive additions together

into a seamless whole. The balance is that with increased softness,

slumping of the clay as the stack is built upwards also becomes a

significant problem. It is clear that one element is personal taste,

which has been found to also be related to raw physical size and

strength. Neil Peterson, at over six feet and well over 200 lbs, is

happy working with a fairly stiff composition, partially due to

larger hand size, but also because of pure power. Darrell Markewitz,

on the other hand, although only a few inches shorter, weighs in at

only 160 lbs, and finds a much softer mix much easier to manipulate,

substituting considerable experience at hand building for strength.

Controlling wall thickness, solid blending of additions and avoiding

slumping are all skills learned through practice.

In a protracted experimental series such as

developed over the years, building furnaces of a fairly consistent

size, in terms of diameter, height and wall thickness were

considered extremely important. Over many furnace builds, it has

certainly been found that controlling the building of clay forms the

size of bloomery furnaces is another example of ‘it’s harder than it

looks’. Experience is required to know how much pressure downwards

needs to be applied to fuse additional lumps of clay material,

without applying so much force that the lower sections distort

outwards. Skilled hands most certainly can effectively create

uniform profiles at desired thickness, but as is so often the case,

experimental workers can simply lack these skills. It should be

noted that archaeological furnaces most often show distinctive

variations in shape and wall thickness illustrative of free hand

building.

Unskilled work producing distorted shape

over a free hand build.

(Note marks from rope binding - discussed later)

Scottish Crannog Centre, 2016

Considering the Use of Forms :

To this end, the simple solution arrived at was

through the use of standard forms to shape diameters. This has

primarily been through the use of sheet metal formed into cylinders,

or employing pre-existing metal containers. Along the way, some

implications towards possible historic methods have been suggested.

Starting with Experiment #3 (June 2003), a sheet

metal cylinder was used to set the internal diameter of the furnace.

Wall thickness was established with each handful of clay material

added as the stack was built up, and the build process is easily

carried out from all sides. One clear advantage was that it was

possible to control this thickness of each addition by pushing

inwards (towards the form) with one hand as pressure as also applied

downwards with the other to assist in fusing the new handful. After

the full build was complete, typically the furnace would be left

overnight with the form in place to stabilize the structure, and to

allow some evening out of the moisture content between the

individual additions of material. The next day, the metal form had

its edges separated (held in place by several small bolts), then

carefully pulled free and removed. This allowed for more even air

drying from both sides. One important modification to the basic

method quickly became clear - the addition of a couple of layers of

paper on to the metal (taped in place newsprint proving simple and

ideal). This created an effective separation, preventing the clay

from sticking to the metal form, making its removal much

easier.

In an early attempt to speed the build process, a

number of furnaces were constructed using two sheet metal forms,

setting inner and outer diameter (so also wall thickness).

Individual lumps of clay material were then dropped down between the

forms, then tamped in place from above with a wooden tool. Although

this certainly made for a faster build process, it generally was

found that it proved more difficult to ensure the separate additions

were fully blended at the seams. Also the downward force of the

packing tool had a tendency, especially at the earlier stages of the

build, of distorting the two forms into more irregular oval shapes.

This also would result in variations in wall thickness over cross

sections.

Build using two forms, just before these were

removed.

Experiment #17 - June 2006

As much as through luck as intent, an ideal metal

form was found, 28 cm in diameter and 40 cm tall, constructed with a

partial end cap that made it more rigid. Although creating a

standardized diameter for test furnaces, use of this form does

require lifting part way through the build sequence. Experience has

shown that typical ‘batch’ of hand mixed clay / sand / manure allows

for building up roughly 25 – 35 cm of wall height, when constructed

to a thickness of between 5 – 8 cm. It has been discovered that

after lifting the metal form clear, the furnace interior can be

re-enforced by filling with a mixture of 50/50 dry sand and wood

ash. This packing also serves to help pull moisture out of the clay

walls. After filling to about 5 cm below the first batch build

height, the form is covered again with newspaper and set on top of

the packing, ready for the next layer.

Dependant on the skill of the workers, and the

plasticity of individual clay mixes, there can be problems with the

lower part of the walls sagging down an outwards as new material is

added on top. This can easily be controlled by spiralling rope over

the outside of the walls. The rope will press into the soft

clay, resulting in a clear impression on the outside surface.

Whether or not this would result in an archaeologically recoverable

feature is uncertain. Repeatedly, it has been seen that the outer

layers of clay do not become hot enough, even over a full smelting

cycle, to actually sinter into a ceramic, and thus could be expected

to simply wash away. (9)

Showing the use of (sand) packing and rope to

stabilize a clay build.

The inset is the mark created by tucking under the loose

end of the rope – as done at the indicated point.

Scottish Crannog Centre, 2016

In a strictly Viking Age context, a rigid form

could be created by use of wooden cooperage. To allow the individual

staves to be removed, these could easily be held loosely in place

into circular form by having an exterior binding of rope (in place

of fixed wooden or metal bands). Use of either a straight

sided cylinder or as an ‘upside down bucket’ for conical profile,

would also allow for consistency of interior diameter over multiple

builds which would have advantages at ‘industrial’ iron production

sites (such as Hals). As a wooden surface, intended to be removed,

is going to result in the same kind ‘clay sticking’ problems as we

have experienced, this suggests the possible use of a separation

layer, with cloth, leather or birch bark all possibilities. If

cloth, there is the possibility finding texture patterns on the

eventually sintered clay walls. Sauder regularly uses a method that

echoes this, by taking a number of thin, narrow wooden strips, which

are fixed to a wooden disk at top and bottom. These are burned out

as part of the drying fire later.

An important consideration overall is that our

use of a metal rigid form will only (easily) allow for a cylindrical

profile to the interior of the furnace. There has been found that

there is some advantage to constructing furnaces with an overall

conical shape. (10) Although most easily achieved through (skilled!)

free hand builds, what kind of alternate internal forms might be

employed?

|

|

|

|

Furnace build using bundled

vegetation as the form.

At Eindhoven, Holland, 2008 (11) *

|

Impressions left on clay walls from

use of an internal wicker frame

(Pictish, 2014 - furnace build illustrated below) |

There is archaeological evidence of the use of

various types of bundled vegetation used to create an internal form.

The example seen above uses river reeds (originally gathered for use

as roof thatching). Cut grasses (crop plants or otherwise) or small,

straight sticks all work as well. Grasses have the advantages of

creating a relatively smooth surface, and also are quite pliable.

With gathered sticks, one potential problem is that clay can be

forced between the gaps, resulting in a rough inner surface to the

furnace. These rough edges can cause the pieces of charcoal to

tumble as they drop downwards as lower levels are consumed. This

rotation can in turn speed the fall of individual ore particles down

the shaft, at least potentially reducing the time for reduction.

(Like any chemical process, the reduction of iron oxide to metallic

iron is not instantaneous.) A potential solution to this

effect would be again to cover the outside of the bundled sticks

with cloth, leather or birch bark. This is likely to produce an

interior surface patterned with random shallow grooves in a wave

like pattern (and again cloth potentially leaving additional texture

impressions).

One clear advantage to the use of bundled

vegetation is the ability of that bundle to flex as the surrounding

clay begins to dry and shrink, most especially the situation with

use of grasses.

Build using a wicker basket internal form,

resulted cracking

Pictish Iron Age Test, June 2014

Use of a rigid form that does not allow for the

shrinking of the drying clay is certainly going to end up causing

major cracking in the body of the furnace. One way to avoid that

problem would be to start a drying fire inside before allowing the

clay any time to significantly air dry, consuming the form material.

There can be other problems associated with this process unless

considerable care is undertaken however, most significantly causing

spalling off of clay fragments because of the explosive expansion of

internal water into steam. (12)

An alternative to an internal form would of

course, use of an exterior one. In actual practice, this proved so

difficult that the idea was abandoned. If the form was the full

height needed for the complete build (so at least 60 cm, possibly

taller), it is not physically possible for a worker to reach down

far enough inside the small space created to effectively apply clay,

at least at the lowest part of the build. (13) It is freely admitted

that there has not been an attempt by this team to employ a shorter

section of metal form, lifting this as the work progresses. How this

might be supported as it was lifted higher would need to be

explored.

A Conclusion :

The nature of clay as initially a plastic

material, transforming to a relatively durable ceramic when exposed

to smelting temperatures, might allow for indications of

building methods to be recovered archaeologically. Generally

however, working furnaces are build out of doors, for obvious fire

control reasons, so used furnaces will be exposed to the full

seasonal variations of rain and temperature. It has been found that

even on multiple firing cycles, the penetration of enough heat to

convert raw clay into a fully sintered ceramic appears to be limited

to roughly 3 to 5 cm. (9) Any wall material to the outer surfaces

quickly washes away as unrecoverable mud. The porous nature of

sintered clays, especially with the use of various temper additives,

combines with exposure to water and the freeze / thaw cycle to

relatively quickly fracture existing walls to small fragments. In

combination any remains are unlikely to fully represent original

wall thickness.

Ancient bloomery iron sites are most likely to be

chosen for their proximity to suitable iron ore, more that any other

single factor. The wide assortment of build materials and styles

employed historically, even within the same cultural group, suggests

a kind of ‘make with what we’ve got’ principle being applied to

furnace construction. Conservation of clay materials is not

considered to be a major concern to ancient builders, as natural

clay deposits, if accessible at all, tend to exist at large volumes.

Use of a form will speed builds, and perhaps most importantly allow

for standardized shapes and diameters. All of these factors would be

desirable for historic iron processing sites where a repeated

production series was undertaken (what has been termed ‘industrial’

level sites).

One very important result of the use of a form is that the support

provided allows for effective construction of much thinner walls

than is possible over free hand building. This may be significant

when considering builds that use a clay liner with earth or turf /

sod construction (again, such as seen at Hals).

* Note : The images used of archaeological furnaces are used

without expressed permission, original source indicated. All other

images by the Author.

Definitions:

a) SHAFT : Here meaning the total height of the furnace interior,

from hard ground surface to top edge.

b) STACK : Here meaning the distance from the centre of the tuyere

to the top of the furnace, which includes the major combustion and

reduction areas. This will be less than the total shaft measurement.

Notes:

1) For a general description of a basic bloomery iron smelting

method, see : 'But If You Don't Get Any IRON...' Towards an

Effective Method for Small Iron Smelting Furnaces, the EXARC

Journal issue 2012/1

http://www.warehamforge.ca/ironsmelting/Get-Iron.pdf

2) A complete description of the overall process and theoretical

conditions inside a bloomery furnace can be found in : Iron in

Archaeology, The European Bloomery Smelters, Padomir Pleiner,

2000 : pages 133 -136

3) A practical guide to building and operating the Flue Tyle furnace

by Skip Williams is available :

http://www.warehamforge.ca/ironsmelting/FlueTyle/index.html

4) This frame of reference is specifically the one of study and

experimental test here. ‘Roman’ furnaces are generally described as

much larger diameters and specifically significantly taller stacks.

With furnace heights over 170 cm (+/-) a natural draft is created,

enough to provide the operating temperatures for effective

reduction. The introduction of water powered systems, starting in

roughly the 800’s and spreading through most of Europe by about 1100

+, allows for much larger furnaces, producing more massive blooms.

5) This has proved the pattern on our earliest tests, where stone

slab furnaces were used. One possibility might be to place the

tuyere not in the centre of one side, but to the corner of the

furnace. This might also help with some of the fitting problems of

providing for the hole needed for the tuyere itself. (Note that this

concept has not been tested by this team)

http://darkcompany.ca/iron/iron0502/index.php?submenu=I

6) ’Sand’ is a bit of a problematic term, as it actually refers to

the particle size, not the mineral composition itself.

Here in Ontario, our locally available sand is finely ground and

water deposited granite, with a high silica content at roughly 70%.

As this discussion is (eventually) aimed at the ongoing experimental

work to the Viking Age Icelandic furnaces excavated at Hals, it

should be noted that any sand available there would have been basalt

source, with a silica content at roughly 50%.

7) Lee Sauder uses a clay with sand mix in the construction of his

furnaces. For an excellent overview and guide to practical bloomery

smelting technique, see his paper : Practical Bloomery Smelting,

(for Materials Research Society) 2001 : https://s3.amazonaws.com/images.icompendium.com/sites/eliz2406/sup/3694985-Practical-Bloomery-Smelting.pdf

8) A (very) brief overview of Michael Nissen’s work (in English) can

be found :

https://ribevikingecenter.dk/en/learn-more/extraction-of-iron.aspx

9) A fuller discussion of both heat penetration effects and

especially furnace erosion over time can be found in : Evidence

of Absence -

Erosion of Bloomery Furnaces, May 2021 :

http://www.warehamforge.ca/ironsmelting/erosion/erosion2021.html

10) As developed by Sauder (with others at his ‘Smeltfest’

workshops), dimensions such that the top opening diameter is equal

to a measurement that matches the placement of the tip of the

tuyere. For an insert tuyere, this point is typically 5 cm beyond

the interior furnace wall. The overall profile becomes a conical

section, the base wider than the top. This can be symmetrical, or

with the rear wall (opposite the tuyere) set horizontal. Both those

shapes are seen in historic furnaces, along with cylindrical builds.

11) Smelting Enriched Bog Ore in a Low Shaft Bloomery,

Johnathan Thorton, 2008. Image from a report on the 3rd

International Symposium on Early Iron, held at Eindhoven, Holland :

http://iron.wlu.edu/reports/Eindhoven%20Smelt%20Report.htm

(note that this image used without expressed permission)

12) This exact problem occurred with Experiment #26 (October 2007)

where prepared commercial clay was cut into brick like slabs to

construct the furnace walls. Despite a 90 minute pre-heat sequence,

steam explosions blew off several pieces of clay (the size of golf

balls, flying 3 – 5 metres!):

http://www.warehamforge.ca/ironsmelting/icelandicA/index.html

13) Using myself as an example, at 175 cm and admittedly fairly long

arms in proportion. My own ‘armpit to first knuckle’ length is 64

cm. This would just barely allow me to reach down inside to possibly

apply clay to the bottom most layer. The working space diameter

would be roughly 45 cm (assuming 7.5 cm wall thickness and 30 cm

ID). Normally two hands are used when applying additional clay

however, one pushing fresh material down and the other to brace

sideways to the existing layer. With my own shoulder width at 50 cm,

I simply can not position both working hands correctly down the

bottom of such a metal tube.

Unless otherwise credited

Images and Text ©

2021 Darrell Markewitz