| ABSTRACT : A Training Course in Iron Smelting,

using a small scale bloomery furnace. Artisan Blacksmith

Darrell Markewitz offers a regular series of weekend long

programs in a number of aspects of traditional

Blacksmithing. Special courses include : layered steels

(pattern welding), bladesmithing / knife making, bronze

casting, iron smelting. Programs held at the Wareham Forge

in Ontario Canada, with remote teaching offered at other

facilities. |

|

Potentially this program will be offered in

2021

Expect a Mid Summer to Early Fall

date

|

Your instructor, Darrell Markewitz, is well known

as a specialist in the Viking Age. He consulted on the

Smithsonian's 'Vikings - North Atlantic Saga' and the

Newfoundland Museum's 'Full Circle - First Contact'. He

designed and produced the exhibit 'World of the Norse' for

the Cranbrook Institute of Science and the 'Norse

Encampment' living history program for Parks Canada. In

2001, he was part of a special research team at L'Anse aux

Meadows NHSC working on presenting Viking Age iron

smelting at the site. Since then he has lead a series of experimental iron

smelts, attempting to discover lost techniques as

they might have been used by the Norse undertaken by the Dark Ages

Re-creation Company. He is one of the core group of

demonstrators and team leaders behind the highly

successful 'Early Iron Symposium' - an annual event held

at the Farmers Museum in Cooperstown NY. He continues to

research, experiment into specifically 'Pre-Medieval'

bloomery furnaces. As well as providing academic papers,

he has worked on projects in Canada, the USA, the UK and

Europe. |

|

Introduction to Smelting Iron is an intensive hands on program, roughly 18 hours in duration. Students will prepare materials, build a smelter, then fire it to produce a workable iron bloom. A bloom weighing roughly 3 - 5 kg is expected from use of about 30 kg of ore. This program does not require any previous metalworking experience. Programs are open to any physically able

people, from young adults onwards. (Aged 16 an up -

see a special note : Teens as

Students). Any students with

"learning \ physical disabilities" need to refer to the

detail section on Course

Requirements. English is the language of

instruction. Sorry - the Wareham Forge is not really

wheel chair accessible. |

|

|

| A number of video segments showing past smelts can be found on Darrell's YouTube channel |

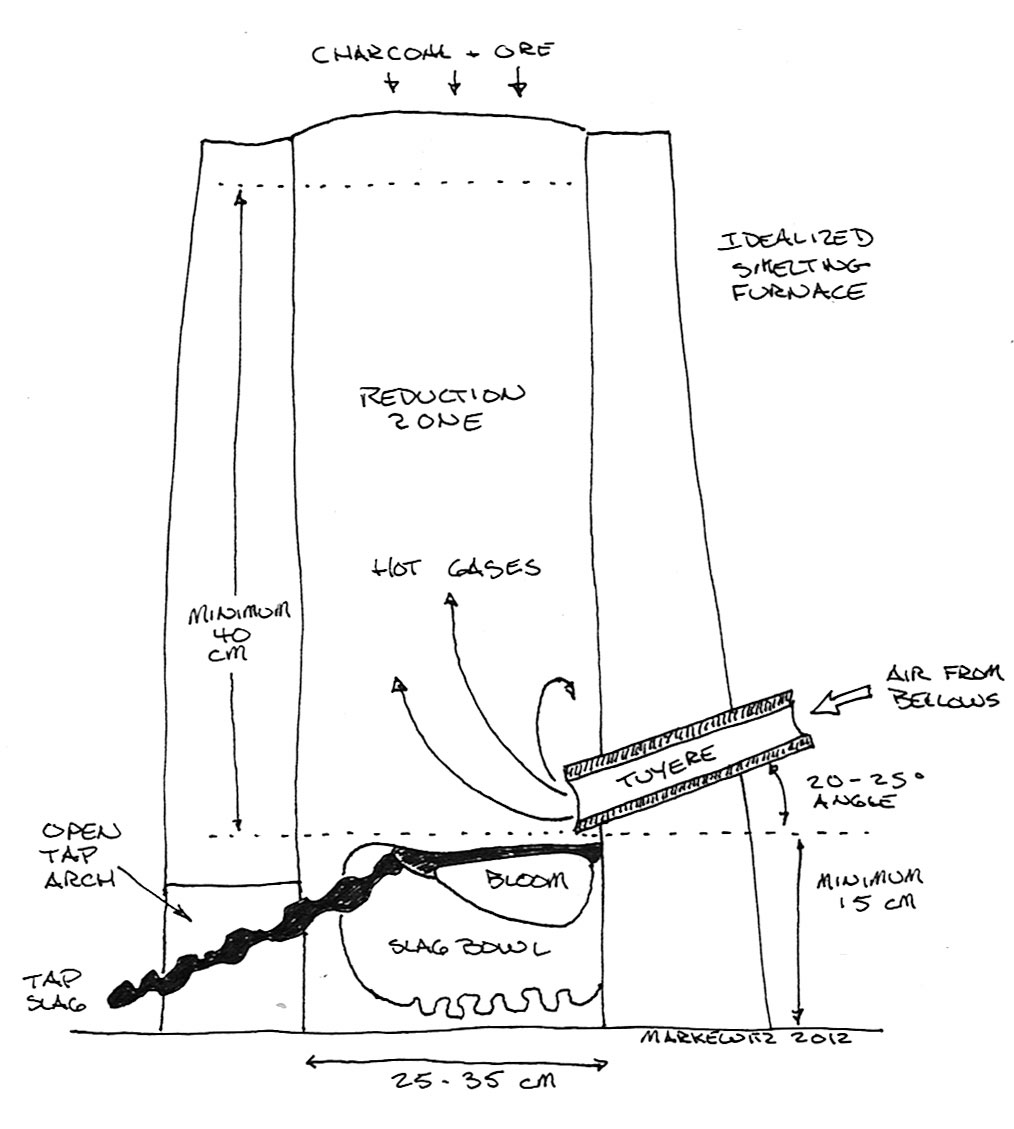

Smelter Plan

|

Smelter Constructed

|

| The course fee includes a handout on disk - and a portion of the bloom created. Students should bring a simple lunches - and 'hand meal' dinner Sunday (something that can be grabbed while managing the smelt!). There will be a handout provided with and overview of technique, equipment and material sources. All required safety equipment will be provided. Students are recommended to wear old clothes, which must be all natural fabrics (cotton ideal) and work boots. A long sleeved shirt and cap is recommended. |

the Wareham Forge

The Hamlet of Wareham, R.R. #2 Proton Station, Ontario

CANADA - N0C 1L0

(519) 923-9219 // E-mail

Interested in adding the drama of an

Iron Smelting Demonstration to YOUR Special Event

or Educational Program?

Darrell has been a featured demonstrator at a number of past

events, including :

2003 / 2004 / 2005 - Early Iron

Symposiums

2005 - CANIRON

V (Annapolis Royal NS)

2008 - Quad

State Roundup (Troy OH)

Check for details on the 'Archaeology &

Experiment - Iron Smelting' Program

For availablity and rates, please contact me.