Air gate power unit

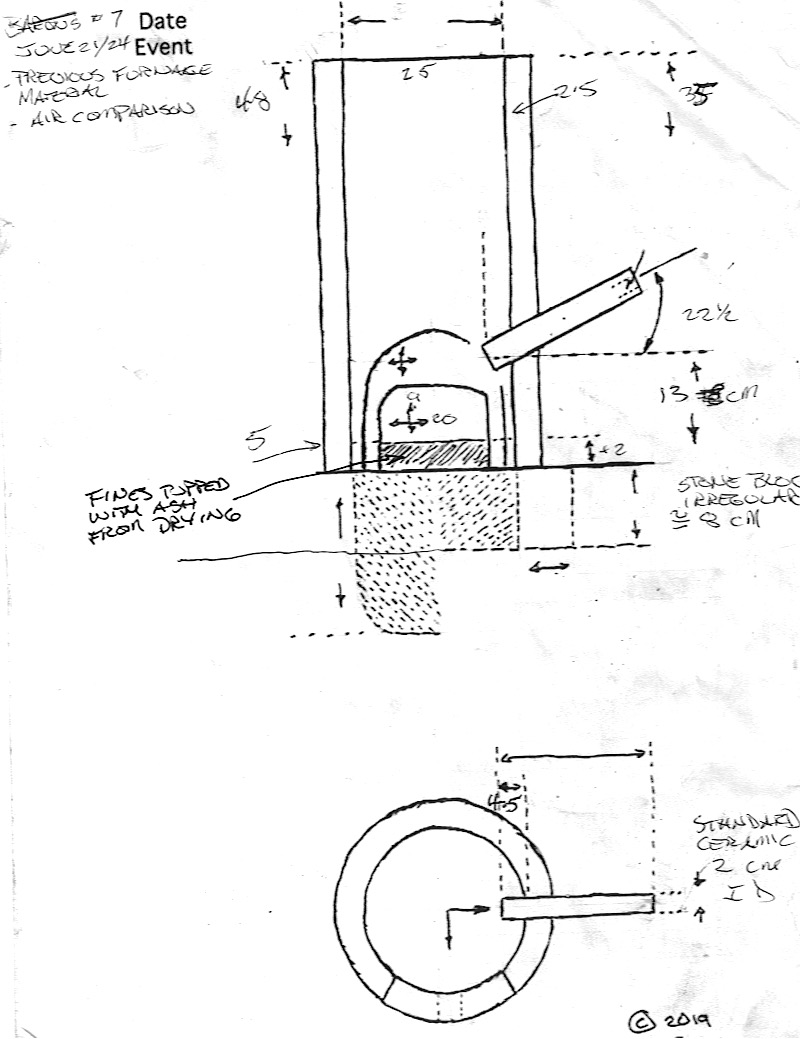

The furnace was the basic Short Shaft type, set on a stone base plinth. One change in build method was the material was made up of a 50 / 50 combination of powdered clay and pulverized furnace wall material taken from the last smelt. This was a combination of partially sintered and baked dry clay / sand / manure mix, with the majority of the organic component burned out through the previous firing. The broken wall pieces remaining from the destructive extraction process last time had been placed in the small cement mixer along with several heavy pieces of steel bar to break down into a sand like consistency.

|

|

| the starting mix,

pulverized furnace to the top |

clay build, after

drying and tuyere set |

The build process (assisted by Rey Cogswell)

was undertaken using a well practised method, with the normally

used steel can used as an internal form. As it turned out, there

was not enough raw material on hand to create as tall a furnace

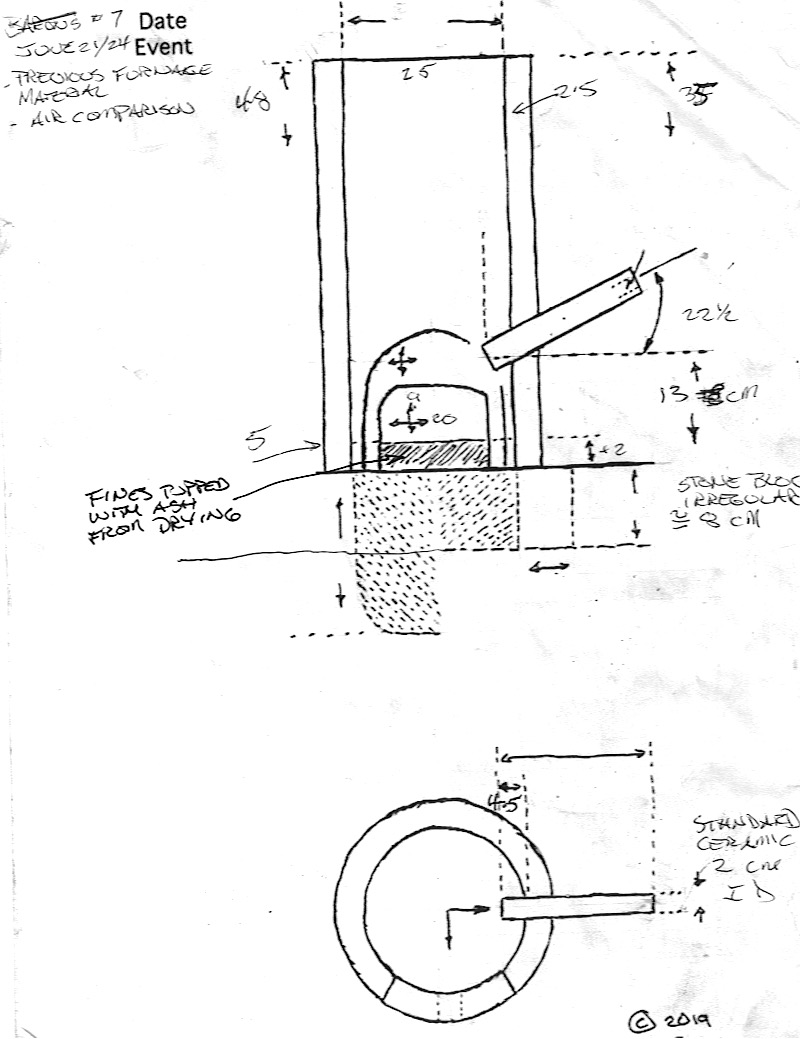

as desired. For the demonstration, a ceramic kiln support tube

was used, again something used with good results in previous

work.

Because of the build process resulting in a stack height less than what is considered effective, a field expedient fix was applied. A discarded metal pail had it's bottom cut off, and this was added on top of the furnace to extend the height potentially a further 46 cm. In practice only half this distance was used, creating the utilized stack measurement at 59 cm.

The smelt would use the proven red iron oxide based analog developed by DARC. (for details)

Internal diameter - 25 cm

Shaft height (total) - 48 cm

Stack height (above tuyere) - 35 cm

Base depth (below tuyere) - 13 cm

Plinth depth (charcoal fines topped with ash) - 10 cm

Tuyere insert - 4.5 cm

Tuyere angle - 22 down

Shaft height (total) - 48 cm

Stack height (above tuyere) - 35 cm

Base depth (below tuyere) - 13 cm

Plinth depth (charcoal fines topped with ash) - 10 cm

Tuyere insert - 4.5 cm

Tuyere angle - 22 down

Because of the build process resulting in a stack height less than what is considered effective, a field expedient fix was applied. A discarded metal pail had it's bottom cut off, and this was added on top of the furnace to extend the height potentially a further 46 cm. In practice only half this distance was used, creating the utilized stack measurement at 59 cm.

Metal pail added to increase available

working stack height, marked by foil tape.

The smelt would use the proven red iron oxide based analog developed by DARC. (for details)

The charcoal was again that made by Ontario

blacksmith Avery Goltz. Primarily from ash, this material was

found to vary considerably in weight, ranging from 1.7 to 2.1

kg for our standard bucket charcoal measure. This most likely

due to absorbed moisture after a year's outdoor storage. An

average weight of 1.9 kg / bucket was used on the data record.

Considering Air :

Again the expectation was that the combination of lower air volume and the pulsing delivery would extend the individual charge burn rates, certainly the situation seen with past smelts using the human powered smelting bellows. For this reason, the pre-heat phase was started earlier than normal (8 AM) with the expectation of slower burn rates into a much longer total working day.

Because of the demonstration / teaching component of this effort, it was decided to link the smelting bellows into the total air system. The intent was that this would be used for short periods, mainly as an experiencial tool, with the main air supply being via the electric blower limited by the sliding gate. The number of individual linked elements would result in air losses at each point. The physical layout also placed the view port at an awkward location, making probing to clear any tuyere blockages more difficult.

the Smelt :

The period from the start of adding charcoal through to considering the furnace burn stable enough to start adding any slag or ore charges was greatly extended. In this case covering almost three hours. The reason for this is criptic at the point this commentary was written ( * ). During this period the air from the blower was blocked and a number of individuals would employ the twin bellows. Measurements were made via a small (and well used) vane styled wind speed gauge. As this gauge is not considered very accurate at this point, the measurements (averages) are best considered only as comparisons :

Most significantly, there would be two major interruptions in electrical power. The first of these occurred just after the first additions of ore, and would last for 7 minutes. During this gap, air was supplied by the bellows only. In the scramble to provide labour, along with inexperienced hands, the net result was a significant drop to furnace temperatures. In an effort to combat this, air flow from the blower, when that returned, was increased significantly. although preserving the smelt as demonstration, this would negate the intent of the experimental aspect however.

The second interruption occurred late in the smelt, and would hasten extraction (described below)

The failure of electric power near the end of the available ore amount resulted in a quick decision to rush straight into extraction. With low experienced team members unsure how to proceed when speed was critical, confusion was the result. Because the exact amount of charcoal required to completely fill the furnace was not recorded, it is not clear exactly how much ore remained in the interior stack as the furnace was quickly emptied. Given that charge levels were at 3 kg ore per bucket volume, this loss would have been in the range of 9 to possibly 12 kg of the added ore, this an amount equal to between a third to even half the total.

Between all the delays, the furnace had already cooled significantly when a mass, basically the entire slag bowl itself, was eventually pulled clear about 20 minutes later.

Given the combination of problems with interrupted and

inconsistent air flow, significant losses due to pre-mature

extraction, it is not surprising the bloom found when all the

depicted slag was struck off was not impressive. In the rush

to move the hot bloom directly to a waiting coal forge under

Mark's hands, the normal 'after initial compaction'

measurement was not made. The best estimate was something in

the range of 2 - 2.5 kg, with the quality assessed as 'very

fragmented'. Mark's attempt to consolidate the bloom was a

huge step forward in his own blacksmithing experience. A

number of small, partially compacted pieces was the end

result.

As the losses due to the early extraction of ore never reduced are unknown, there is no effective way to calculate a yield. Direct ore input to bloom output would be about 8% / more reasonable would be ore without loss in the emptied stack, so closer to 12%.

(*) Another important failure in record keeping.

For a number of reasons, this report was written fully two months after this event. Memory fades, so with inconsistent written records (Willow's full name never written down as example) and very limited photographs available, reconstructing details becomes difficult.

Considering Air :

Again the expectation was that the combination of lower air volume and the pulsing delivery would extend the individual charge burn rates, certainly the situation seen with past smelts using the human powered smelting bellows. For this reason, the pre-heat phase was started earlier than normal (8 AM) with the expectation of slower burn rates into a much longer total working day.

Complete air supply system :

blower / gate / sliding plate / Y tube to bellows / air gauge / view port / tuyere

blower / gate / sliding plate / Y tube to bellows / air gauge / view port / tuyere

Because of the demonstration / teaching component of this effort, it was decided to link the smelting bellows into the total air system. The intent was that this would be used for short periods, mainly as an experiencial tool, with the main air supply being via the electric blower limited by the sliding gate. The number of individual linked elements would result in air losses at each point. The physical layout also placed the view port at an awkward location, making probing to clear any tuyere blockages more difficult.

the Smelt :

Team:With a larger than normal team, several new to the process, and the added complications and distractions of a public demonstration, keeping work process consistent proved difficult. To further complicate the smelt, the weather contributed high, gusting winds and several periods of driving rain. New hands keeping the data records would lead to interpretation problems after the fact and some loss of information.

Darrell Markewitz - smelt master

Rey Cogswell - lead hand / record keeping

Kiernan Rodgers - charcoal / ore additions

Autumn - charcoal / ore additions

Mark Paisley - striker

Neil Peterson - assisting

The period from the start of adding charcoal through to considering the furnace burn stable enough to start adding any slag or ore charges was greatly extended. In this case covering almost three hours. The reason for this is criptic at the point this commentary was written ( * ). During this period the air from the blower was blocked and a number of individuals would employ the twin bellows. Measurements were made via a small (and well used) vane styled wind speed gauge. As this gauge is not considered very accurate at this point, the measurements (averages) are best considered only as comparisons :

Darrell = 35 kphAt the end of this test, the electric blower to pulsing plate system was initally adjusted to deliver the same 35 kph measurement.

Neil = 32 - 28 kph

Rey = 29 - 19 kph

? = 35 kph

?? = 28 - 21 kph

Most significantly, there would be two major interruptions in electrical power. The first of these occurred just after the first additions of ore, and would last for 7 minutes. During this gap, air was supplied by the bellows only. In the scramble to provide labour, along with inexperienced hands, the net result was a significant drop to furnace temperatures. In an effort to combat this, air flow from the blower, when that returned, was increased significantly. although preserving the smelt as demonstration, this would negate the intent of the experimental aspect however.

The second interruption occurred late in the smelt, and would hasten extraction (described below)

The established method of adding a quantity of iron rich tap slag as starting charges, 1 kg amounts against charcoal bucket, was used at the start to a total of 4 kg. Also as normal practice, ore charges would increase regularly from a starting amount of 1 kg per charcoal bucket measure to 3 kg additions.

Pre-heat time : 2 hoursAs was expected, the burn times with the reduced air volumes mimicking twin bellows delivery being much longer than that produced via direct input from high volume electric blowers. This clearly marks a significant difference between historic and modern equipment for air delivery.

Total smelt time : 12:28 (to extraction)

Ore addition time : 297 minutes (4:57)

Charcoal burn rate :12.0 min/kg (during ore)

Ore addition rate : 11.2 min/kg

The failure of electric power near the end of the available ore amount resulted in a quick decision to rush straight into extraction. With low experienced team members unsure how to proceed when speed was critical, confusion was the result. Because the exact amount of charcoal required to completely fill the furnace was not recorded, it is not clear exactly how much ore remained in the interior stack as the furnace was quickly emptied. Given that charge levels were at 3 kg ore per bucket volume, this loss would have been in the range of 9 to possibly 12 kg of the added ore, this an amount equal to between a third to even half the total.

Between all the delays, the furnace had already cooled significantly when a mass, basically the entire slag bowl itself, was eventually pulled clear about 20 minutes later.

As the losses due to the early extraction of ore never reduced are unknown, there is no effective way to calculate a yield. Direct ore input to bloom output would be about 8% / more reasonable would be ore without loss in the emptied stack, so closer to 12%.

(*) Another important failure in record keeping.

For a number of reasons, this report was written fully two months after this event. Memory fades, so with inconsistent written records (Willow's full name never written down as example) and very limited photographs available, reconstructing details becomes difficult.